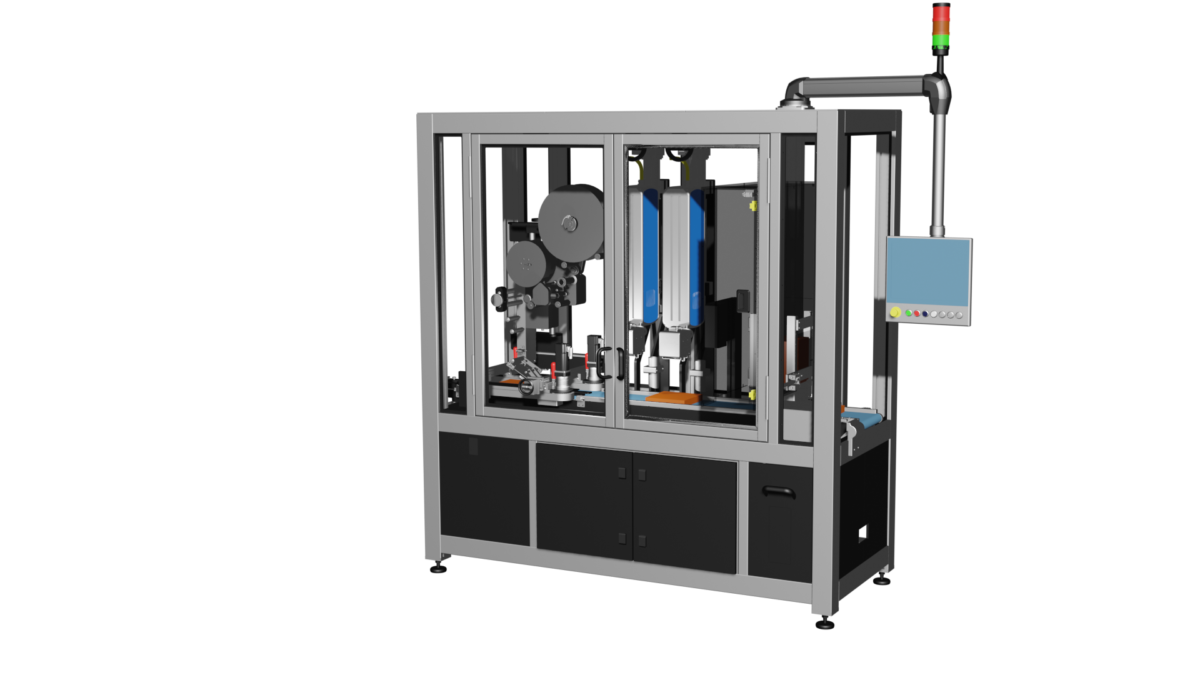

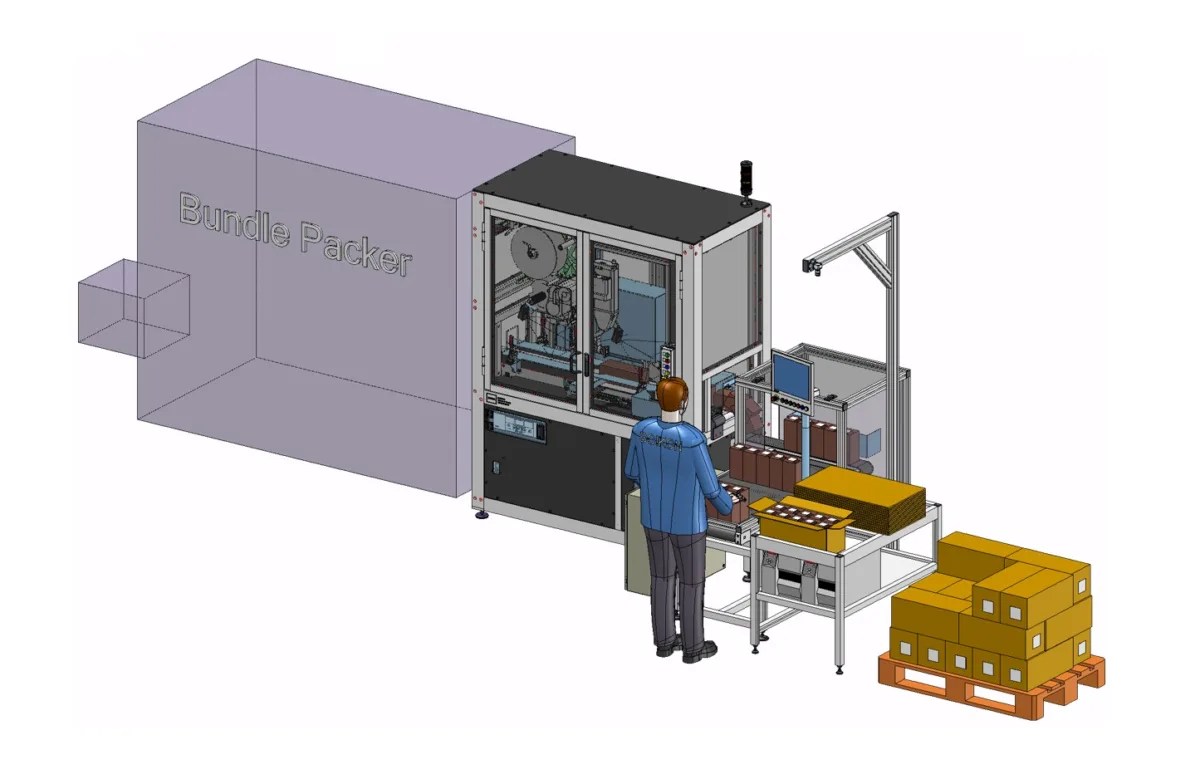

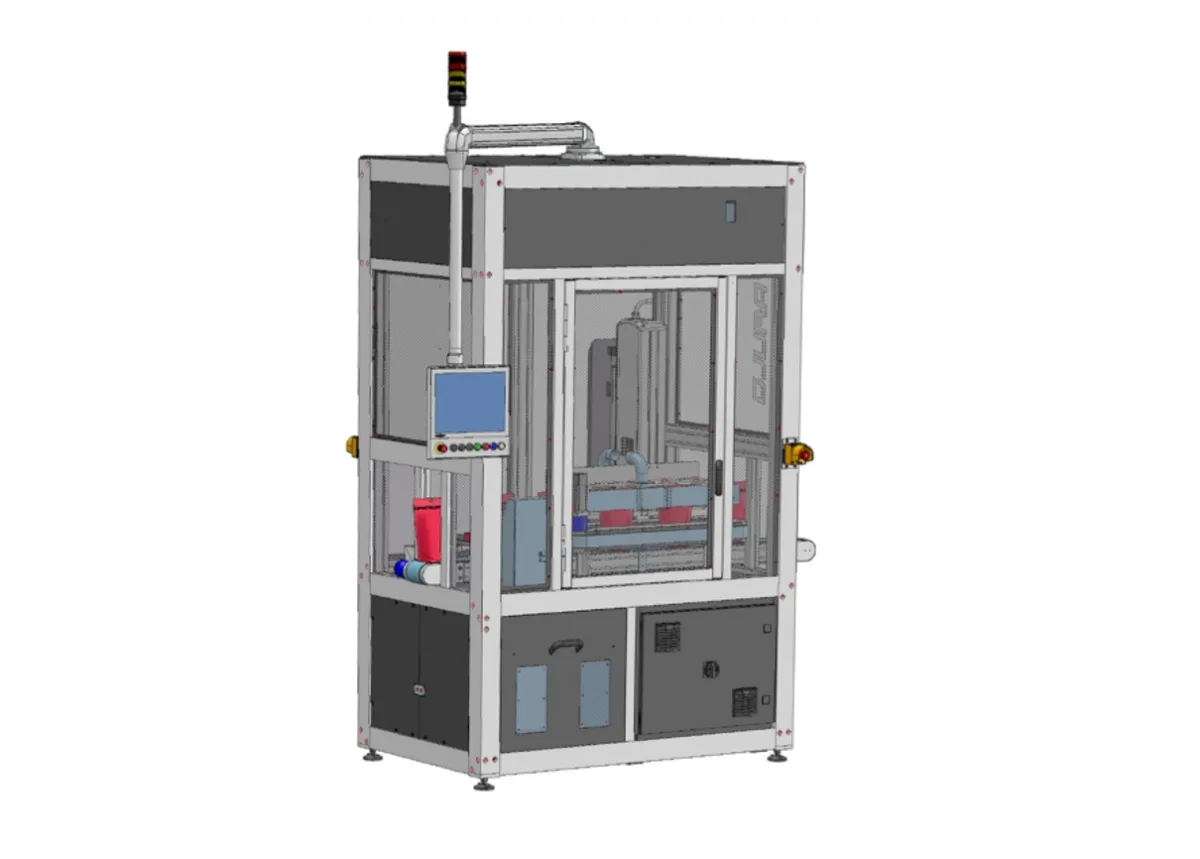

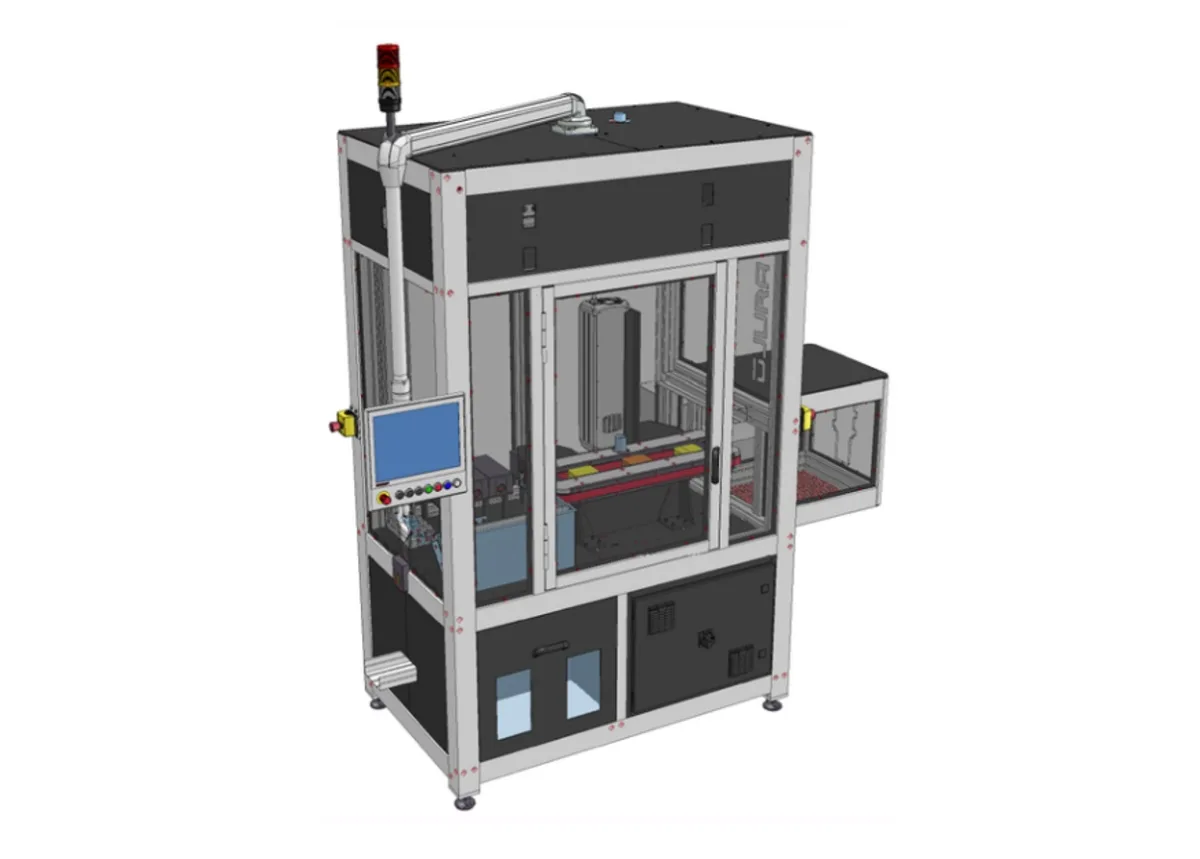

The DJURA Cigar is specifically designed for serialization of cigar packaging. Despite its many functionalities, the Djura Cigar occupies less than two square meters of space.

Functionalities

- Packaging recognition (ensures production of the correct product)

- Packaging quality control (position and orientation, presence and position of seal or tax stamp, and EAN code verification)

- Print surface recognition (always a centered code) Dual laser coding systems (for European and Russian markets)

- Labeling capability

- Code readability verification

- Reject system for rejected packages

Features

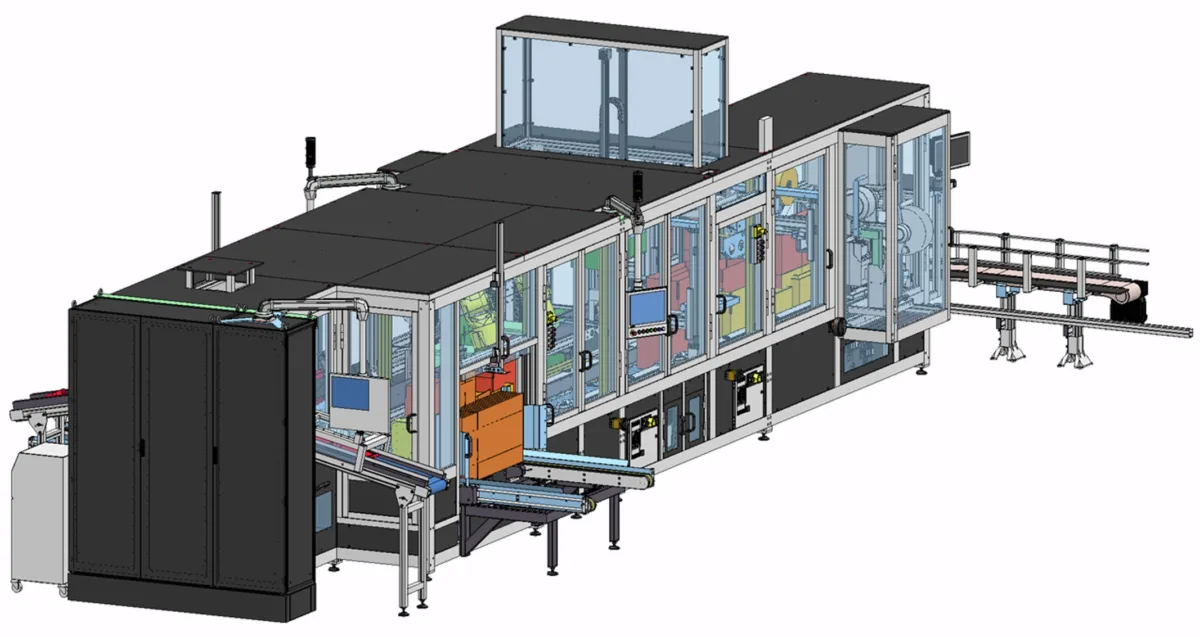

- Independent of the original equipment manufacturer (OEM) of existing machinery/production line (standalone machine).

- Independent of the EU member state. Serialization is done according to the applicable guidelines of the respective member state.

- Compliance with Russian laws and regulations.

- Serialization of all packaging materials with a single laser coding system.

- One control system for serialization and all aggregation levels.

- Serialization takes place after the final reject (checkweigher), making the system ready for the digital tax stamp.

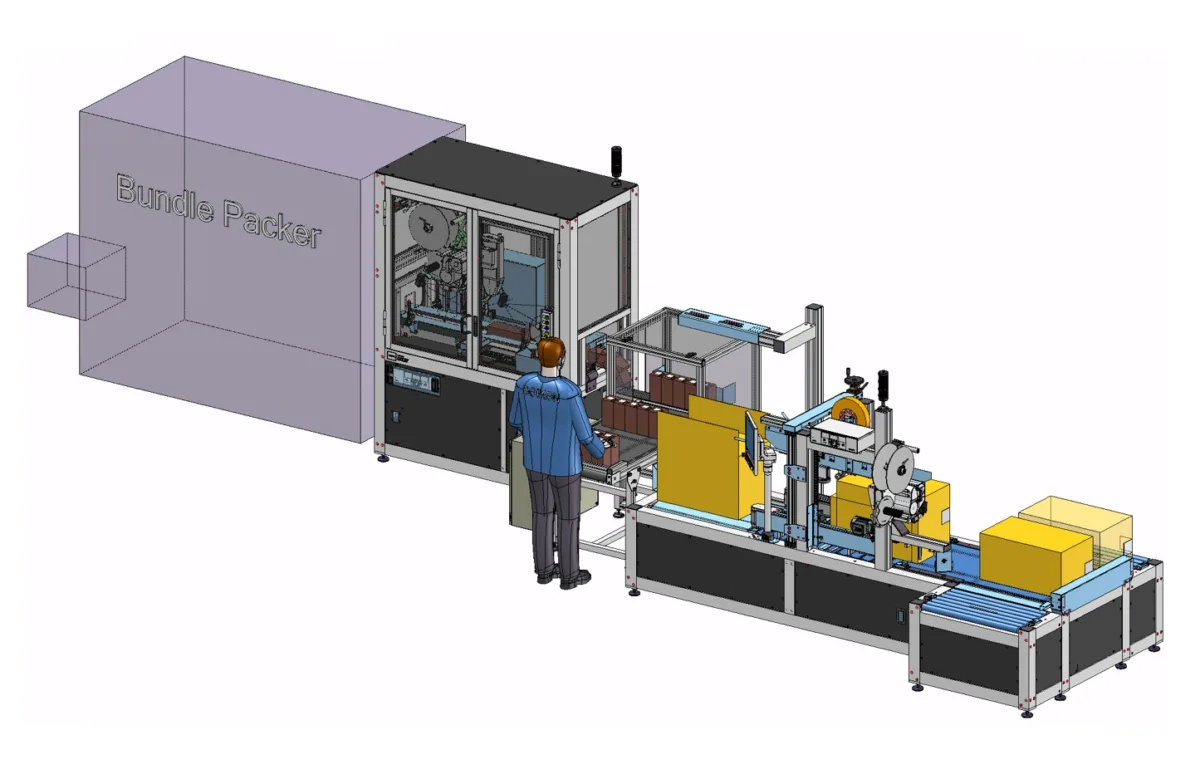

- No changes in the overall layout of the entire production line. Systems are integrated into the current layout.