About DJURA

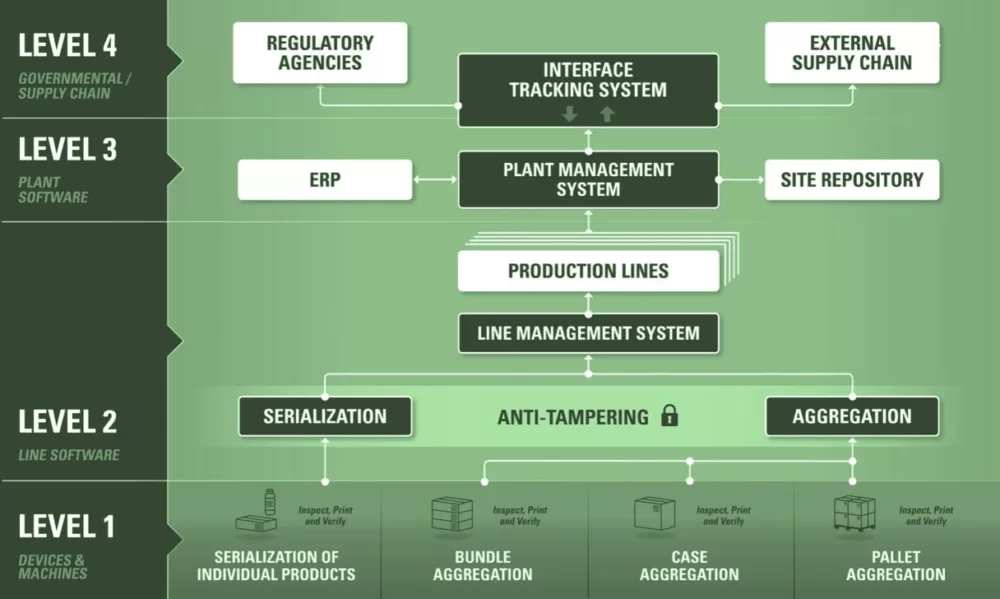

Does your company deal with laws and regulations regarding authenticity and verification? DJURA’s track & trace technology is here to support you. DJURA is the proven solution for any production chain where quality control is key, through a three-stage process of serialization, aggregation and anti-tampering.

Each product is provided with a unique code that is encrypted and logged, keeping the product traceable and verifiable at any point in the logistical process, from the factory to the shelf. Whether it is an individual item or an entire pallet, DJURA keeps an eye out for the goods.

The track & trace technology of DJURA has been used for many years in various industries, including the pharmaceutical and tobacco industries, where authenticity and traceability play a key role. The 100% closed and reliable track & trace system ensures a validated serialization, aggregation, and production process. Thanks to intelligent analysis of production data and user feedback, DJURA becomes a little smarter every day.

TRACEABLE AND AUDITABLE, FROM THE FACTORY TO THE SHELF

- DJURA’s efficient laser technology can provide up to 160 prints per minute.

- The intelligent algorithms of the coding equipment guarantee 99.9% accuracy, up to 99.98% in practice.

- A DJURA machine usually takes up no more than 1m2 of space and can be integrated into any production process.

- The underlying software provides all the capabilities for advanced data analysis, effortlessly detecting any issue in the production process.